Fault Tree Analysis

Fault tree analysis (FTA) is a top down, deductive failure analysis in which an undesired state of a system is analyzed using Boolean logic to combine a series of lower-level events. This analysis method is mainly used in the fields of safety engineering and reliability engineering to understand how systems can fail, to identify the best ways to reduce risk or to determine (or get a feeling for) event rates of a safety accident or a particular system level (functional) failure. FTA is used in the aerospace, nuclear power, chemical and process, pharmaceutical, petrochemical and other high-hazard industries; but is also used in fields as diverse as risk factor identification relating to social service system failure. FTA is also used in software engineering for debugging purposes and is closely related to cause-elimination technique used to detect bugs.

In aerospace, the more general term "system Failure Condition" is used for the "undesired state" / Top event of the fault tree. These conditions are classified by the severity of their effects. The most severe conditions require the most extensive fault tree analysis. These "system Failure Conditions" and their classification are often previously determined in the functional Hazard analysis.

Usage

Fault Tree Analysis can be used to:

- understand the logic leading to the top event / undesired state.

- show compliance with the (input) system safety / reliability requirements.

- prioritize the contributors leading to the top event - Creating the Critical Equipment/Parts/Events lists for different importance measures.

- monitor and control the safety performance of the complex system (e.g., is a particular aircraft safe to fly when fuel valve x malfunctions? For how long is it allowed to fly with the valve malfunction?).

- minimize and optimize resources.

- assist in designing a system. The FTA can be used as a design tool that helps to create (output / lower level) requirements.

- function as a diagnostic tool to identify and correct causes of the top event. It can help with the creation of diagnostic manuals / processes.

Graphic Symbols

The basic symbols used in FTA are grouped as events, gates, and transfer symbols. Minor variations may be used in FTA software.

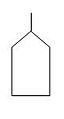

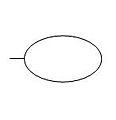

Event Symbols

Event symbols are used for primary events and intermediate events. Primary events are not further developed on the fault tree. Intermediate events are found at the output of a gate. The event symbols are shown below:

The primary event symbols are typically used as follows:

- Basic event - failure or error in a system component or element (example: switch stuck in open position)

- External event - normally expected to occur (not of itself a fault)

- Undeveloped event - an event about which insufficient information is available, or which is of no consequence

- Conditioning event - conditions that restrict or affect logic gates (example: mode of operation in effect)

An intermediate event gate can be used immediately above a primary event to provide more room to type the event description. FTA is top to bottom approach.

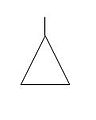

Gate Symbols

Gate symbols describe the relationship between input and output events. The symbols are derived from Boolean logic symbols:

The gates work as follows:

- OR gate - the output occurs if any input occurs

- AND gate - the output occurs only if all inputs occur (inputs are independent)

- Exclusive OR gate - the output occurs if exactly one input occurs

- Priority AND gate - the output occurs if the inputs occur in a specific sequence specified by a conditioning event

- Inhibit gate - the output occurs if the input occurs under an enabling condition specified by a conditioning event

Transfer Symbols

Transfer symbols are used to connect the inputs and outputs of related fault trees, such as the fault tree of a subsystem to its system. NASA prepared a complete document about FTA through practical incidents.

No comments:

Post a Comment